Task dependencies and sequencing

Automatically order maintenance tasks based on priority and dependencies to minimize downtime.

Automatically sequence and assign tasks based on priority, skills, and equipment availability. Our Maintenance Scheduling API increases asset uptime, technician productivity, and compliance without adding administrative burden.

Let Timefold do the heavy lifting

Running maintenance in high-demand environments is complex.

Automatically order maintenance tasks based on priority and dependencies to minimize downtime.

Ensure only qualified technicians are assigned to specialized or high-risk tasks.

Avoid overlap for shared tools, restricted zones, or critical machinery.

React instantly when work orders change, parts are delayed, or urgent issues arise.

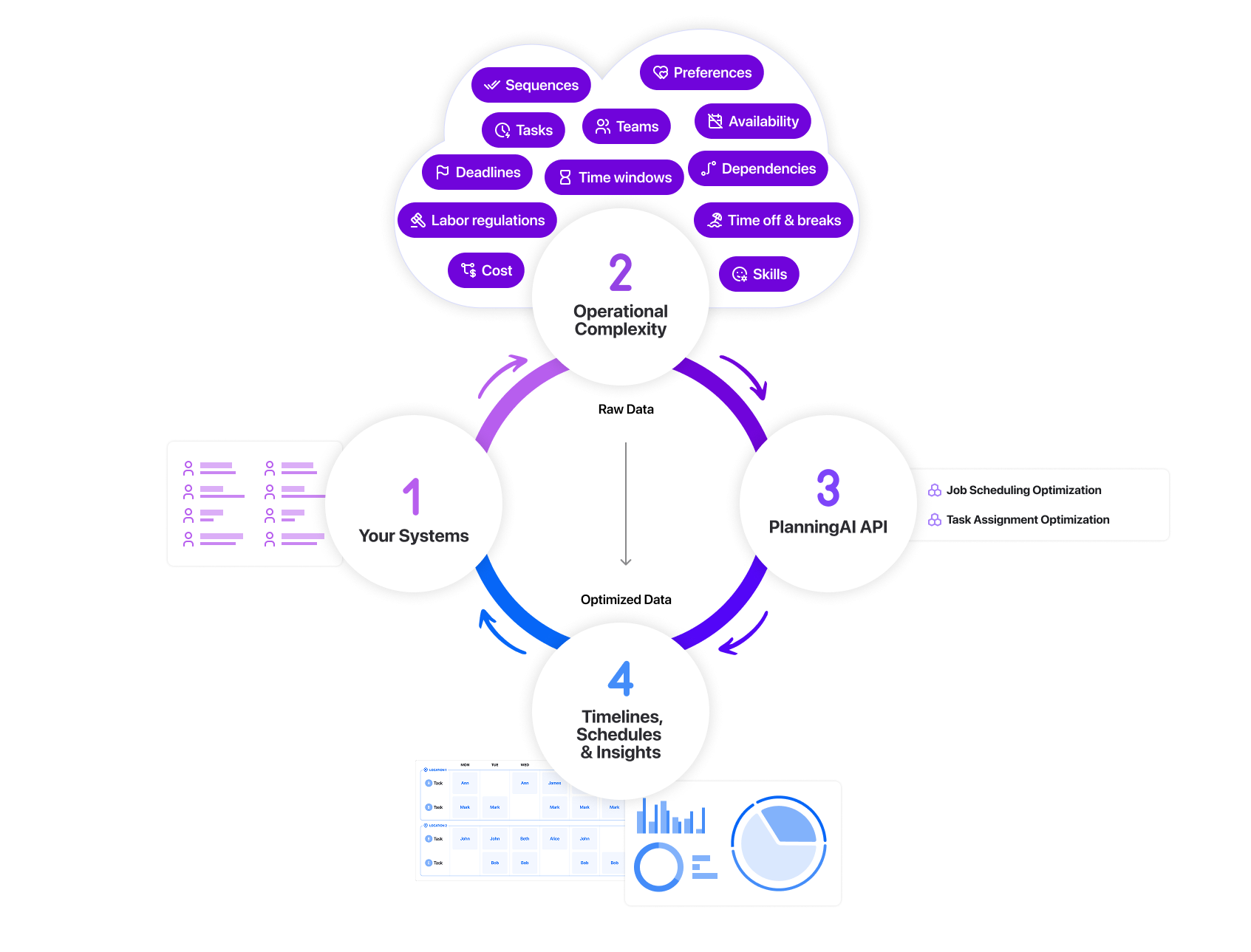

The PlanningAI cycle

Feed your maintenance data like assets, tasks, priorities, technician skills, and access constraints into the Timefold API.

What route optimization with PlanningAI delivers

-18 %

Maintenance cost

+ 25 %

Technician productivity

+30 %

Faster issue resolution

1 click

To re-optimize on the fly

Plug in best-of-breed optimization technology

We compiled 20+ years of domain experience in a backend production scheduling solution.

Multi-resource coordination

Assign multiple technicians, machines, or tools to tasks that require collaboration.

Safety and compliance

Enforce safety standards and maintenance intervals automatically.

Cost optimization

Balance preventive and corrective maintenance to control cost.

Fair workload distribution

Distribute work evenly across technicians to prevent fatigue.

Priority-based planning

Ensure high-impact assets and urgent requests are handled first.

Predictive readiness

Plan upcoming maintenance windows based on usage and reliability data.