Job sequencing and setup time

Automatically order jobs to reduce changeovers, respect setup, and avoid costly downtime.

Run production faster with automatically optimized job and machine schedules. Our Task Assignment Optimization API builds executable plans that respect setup times, skills, and capacity while balancing cost, throughput, and delivery commitments.

Let Timefold do the heavy lifting

Running discrete manufacturing means managing hundreds of interdependent jobs across machines, tooling, people, and shifts.

Automatically order jobs to reduce changeovers, respect setup, and avoid costly downtime.

Match every job to the right machine and qualified operator to keep lines productive and safe.

Avoid conflicts when multiple jobs compete for the same resource, fixture, or workcell.

Reoptimize instantly when priorities shift, a line goes down, or a high-priority order needs to be inserted.

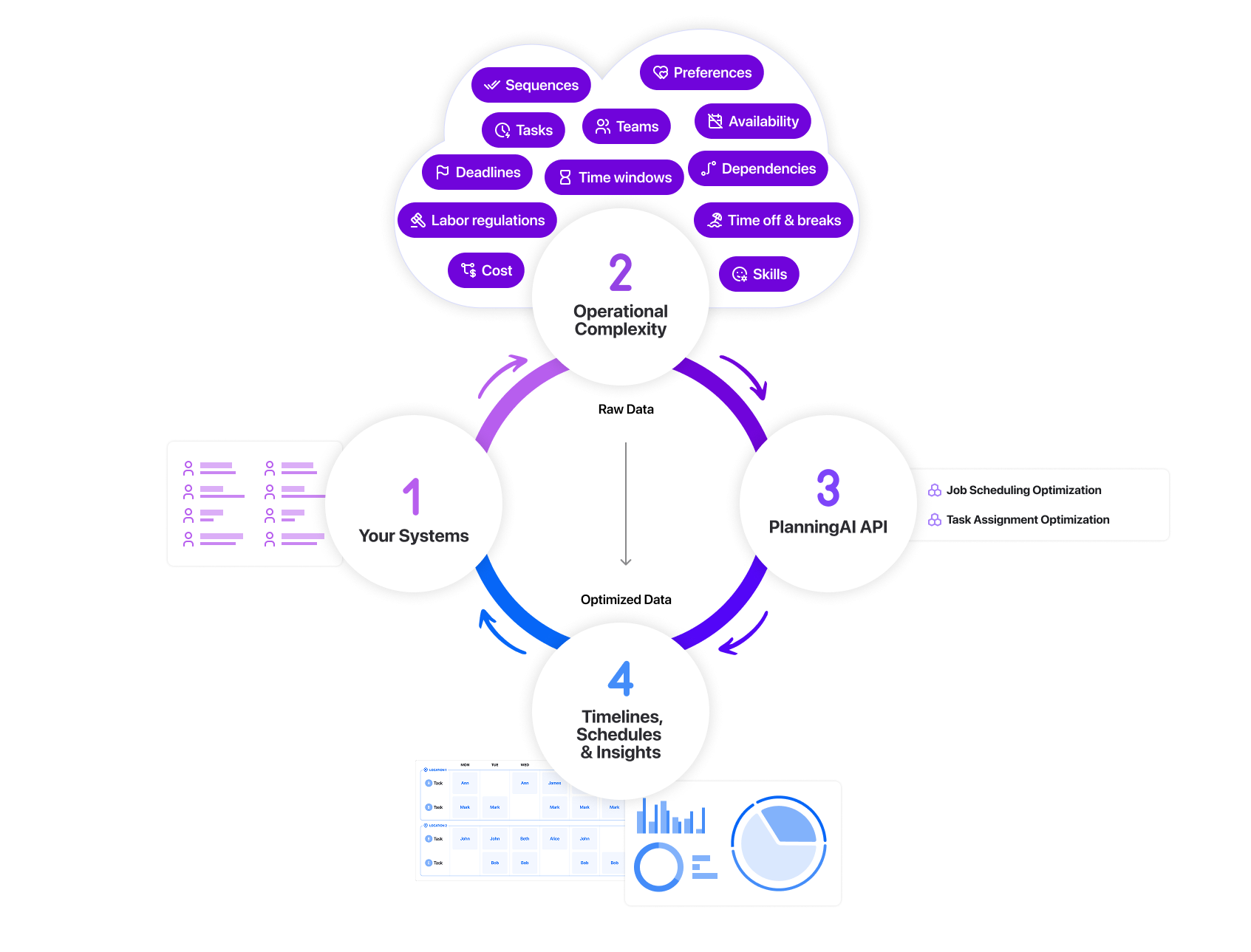

The PlanningAI cycle

Feed your manufacturing data like orders, jobs, routings, setup times, changeover rules, machine calendars, operator availability, and maintenance windows into the Timefold API, and get back a complete, feasible production schedule that respects capacity, deadlines, and constraints on the shop floor.

• Scheduling engine built on 20+ years of expertise

• 70+ constraints preloaded for real-world manufacturing complexity

• Scalable to thousands of jobs per day

• Compliant and secure by design

What route optimization with PlanningAI delivers

1 click

to create and update full production schedules

Up to 25 %

increase in throughput efficiency

+20 %

reduction in changeover and setup time

-10 %

shorter lead times and lower WIP

Plug in best-of-breed optimization technology

We compiled 20+ years of domain experience in a backend production scheduling solution.

Higher throughput

Eliminate idle gaps between operations and keep machines producing.

Smarter resource utilization

Balance work automatically across machines, operators, tooling, and lines to prevent bottlenecks and underuse.

Flexibile resilience

React instantly when a machine goes down, material is late, or a rush order appears, without rebuilding the entire plan.

Improved delivery reliability

Generate schedules that are realistic, explainable, and compliant with every constraint.

Lower operational cost

Cut overtime, reduce unnecessary changeovers, and limit expensive downtime.

Strategic planning

Gain the power to align production with what matters most, whether it is on-time delivery, throughput, or cost per unit.