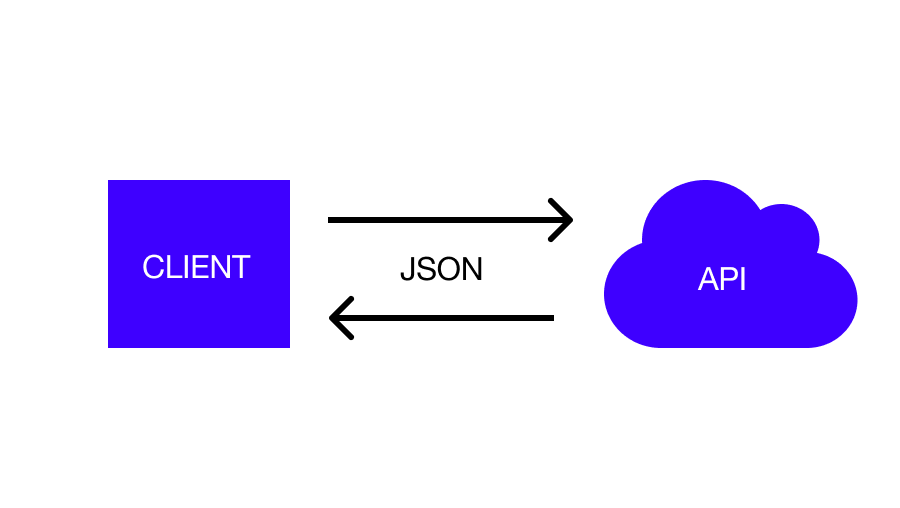

REST API - JSON in/out

Harness the power of AI-driven optimization technology by sending your planning problem to our REST API and we return you an optimized solution. Catering to the complexities of shipping orders faster.

Your preferred way of hosting

Host Timefold on-premise via a docker image and your preferred hosting solution. Or leverage our technology via the Timefold hosted cloud platform.

Designed for full flexibility

- Adapt in real-time to changes in the environment, such as new orders, delays or employee availability.

- Continuous planning, allowing to plan ahead for days, weeks or even months, while only publishing the short term planning.

- Remain in control with manual pinning of specific routes, drivers or vehicles.

For operations managers

Find the quickest warehouse routes

Contact us to explore how our advanced optimization can enhance your picking efficiency and reduce operational costs. Our automated planning adapts to your warehouse layout and product placement, ensuring optimal picking results.

Talk to usFor Order Picking SaaS

Integrate the best solver

Enhance your Order Picking Solution with Timefold's advanced scheduling capabilities. Seamlessly integrate Timefold into your platform, empowering you to elevate your core features

Talk to usOptimized Warehouse Order Picking scheduling for your business constraints and rules

Minimized Travel Distance

Efficiently minimize trolley travel distances

Time Windows

Define specific time frames during which orders must be picked and packed.

Product Priority

Prioritize the picking of certain products based on factors like demand, shelf life, or customer preferences.

Batch Picking

Optimize for picking multiple orders at once to reduce travel time within the warehouse.

Prevent Mixing

Prevent mixing items from different orders in the same container

Trolley Slot Allocation

Allocate sufficient containers for each order on a trolley

Capacity Management

Maintain optimal container capacity to avoid exceeding item volume

Order Splitting Reduction

Minimize the division of orders among different trolleys for enhanced efficiency

Time Windows

Ensure specific team members are always on the same shift

Safety Rules

Ensure that picking routes adhere to safety regulations and avoid hazardous areas.

Picker Fairness

Balance the workload among pickers to prevent overburdening certain individuals.

Custom constraints?

Your unique business rule can be translated into an actionable constraint.

18 years of Planning Optimization

18 years ago I started OptaPlanner as an Open Source project and built a team around it, at Red Hat.

Geoffrey De Smet - Co-founder & CTO, Timefold

Now we are continuing the project as a dedicated company under the Timefold brand. Improving on our already existing product, building with the co-creators of OptaPlanner.

Related planning models

Field Service Routing

Optimizes routes for technicians or service workers to efficiently reach multiple locations, minimizing travel time and costs while maximizing customer satisfaction.

Read moreLast Mile Delivery Routing

Plans the most efficient routes for delivering goods from distribution centers to customers' doorsteps, considering factors like traffic, delivery windows, and package characteristics to minimize costs and delivery times.

Read moreVehicle Routing (VRP)

Determines the most efficient routes for a fleet of vehicles to visit multiple destinations, considering factors like distance, vehicle capacity, time windows, and customer preferences to optimize delivery or service operations.

Read more